NORDIC ACOUSTICS WITH A GREEN NARRATIVE

Explore our GreenOption acoustic panels, featuring an impressive 65% recycled felt backing!

At BY VENØ, we craft FSC®-certified, eco-conscious acoustic panels in Denmark, meticulously designed to enrich room acoustics. The GreenOption acoustic panels offer the same remarkable sound performance as always, now available in an even more sustainable material with an impressive 65% recycled felt backing.

This stunning panel embodies more than iconic Scandinavian design – it also tells stories from Nordic football clubs. The recycled material, made from artificial turf from these football pitches, is completely unique within this type of product on the market!

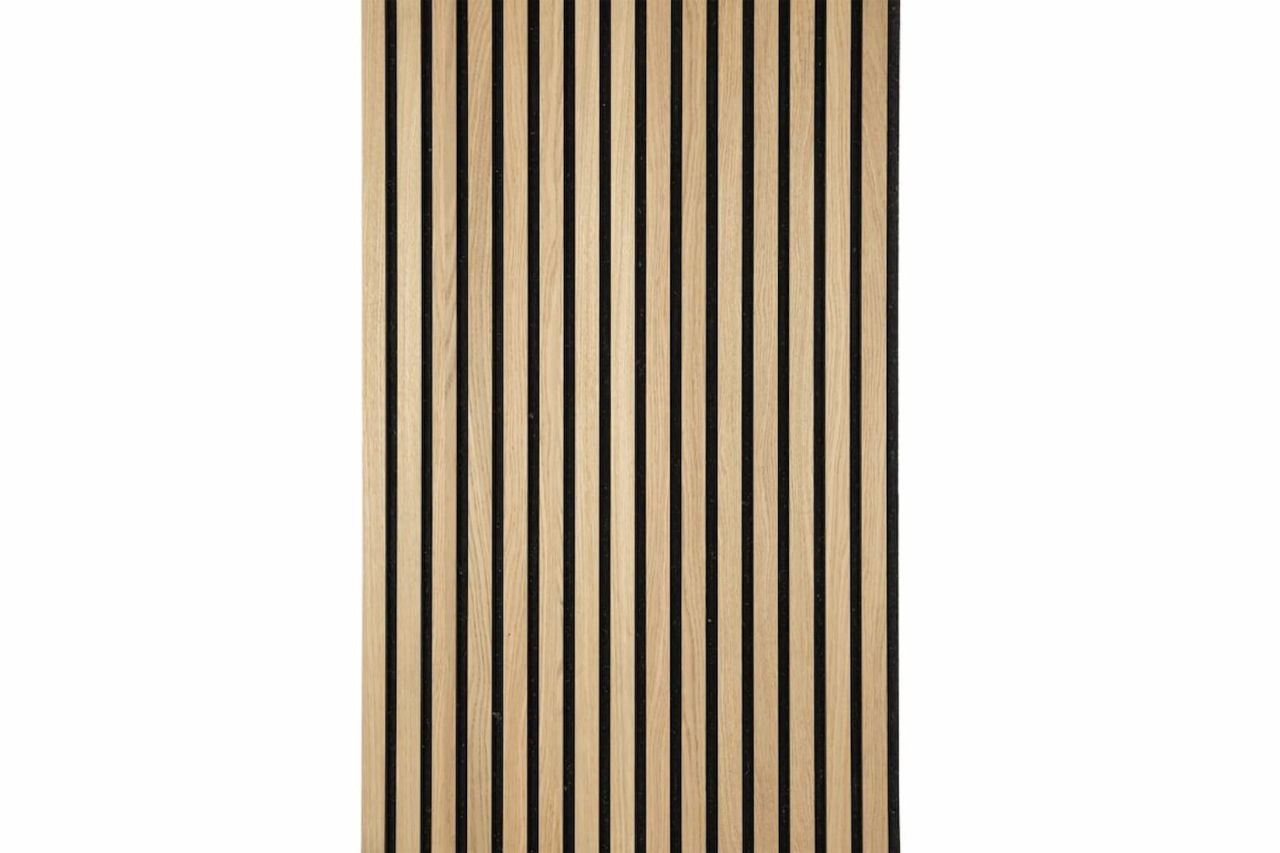

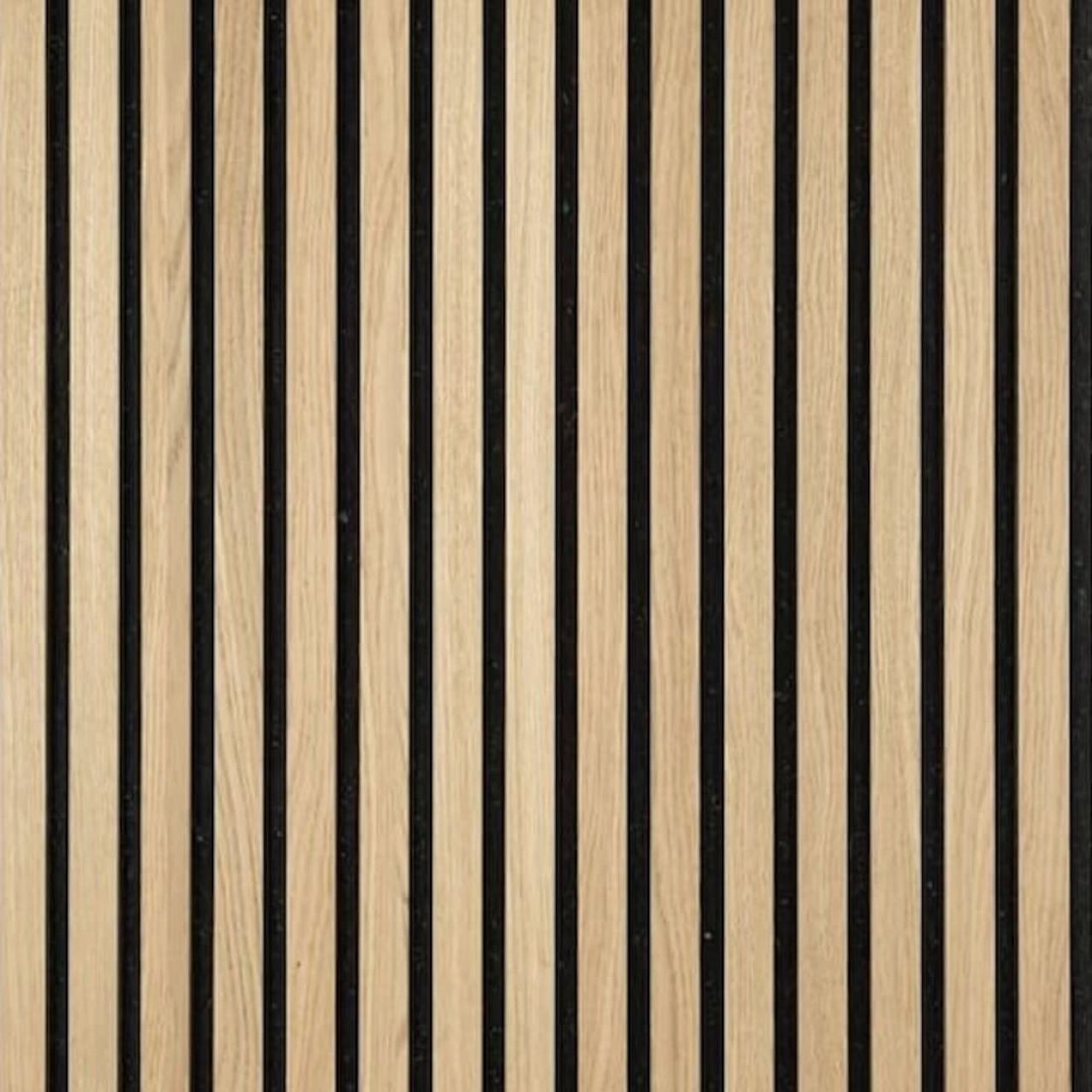

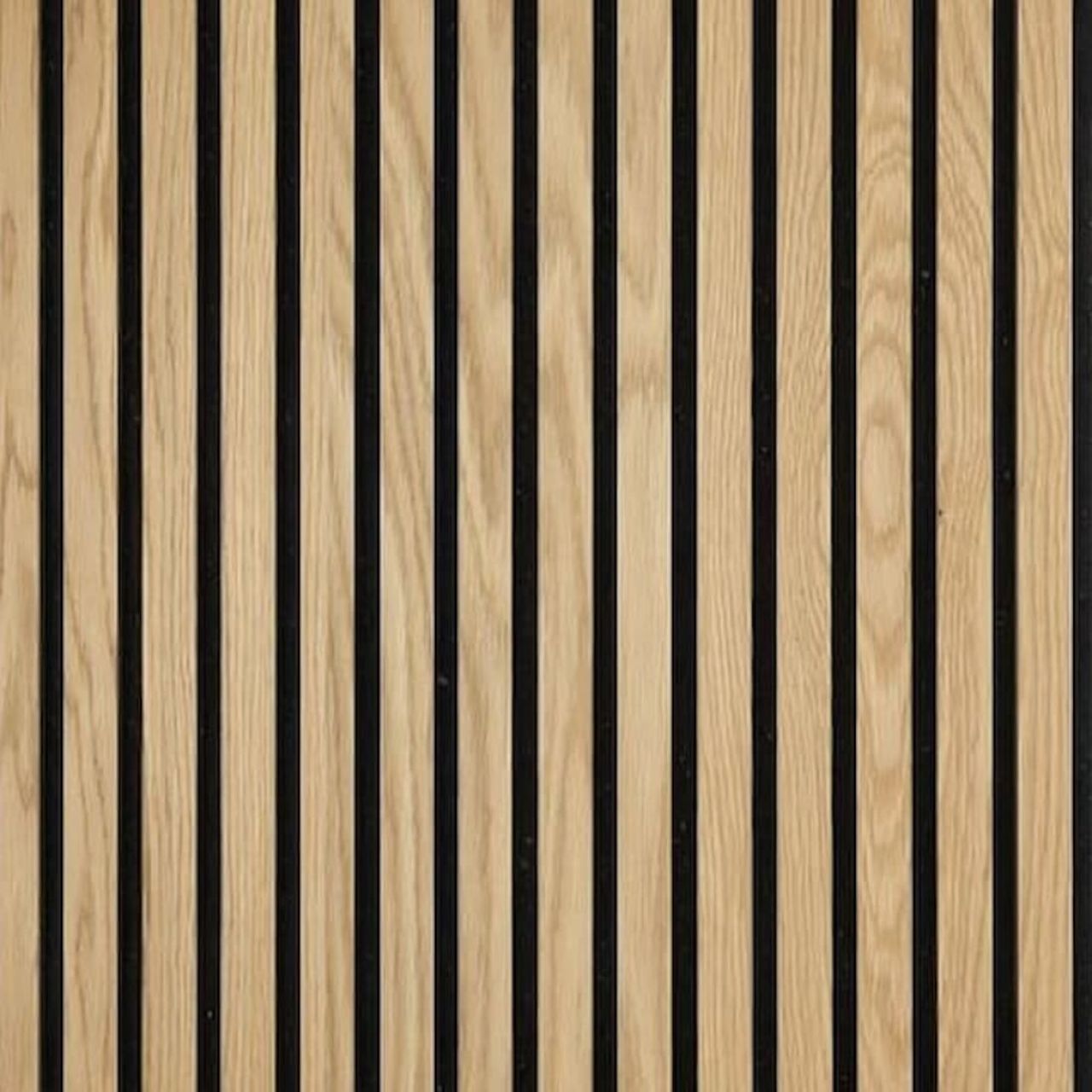

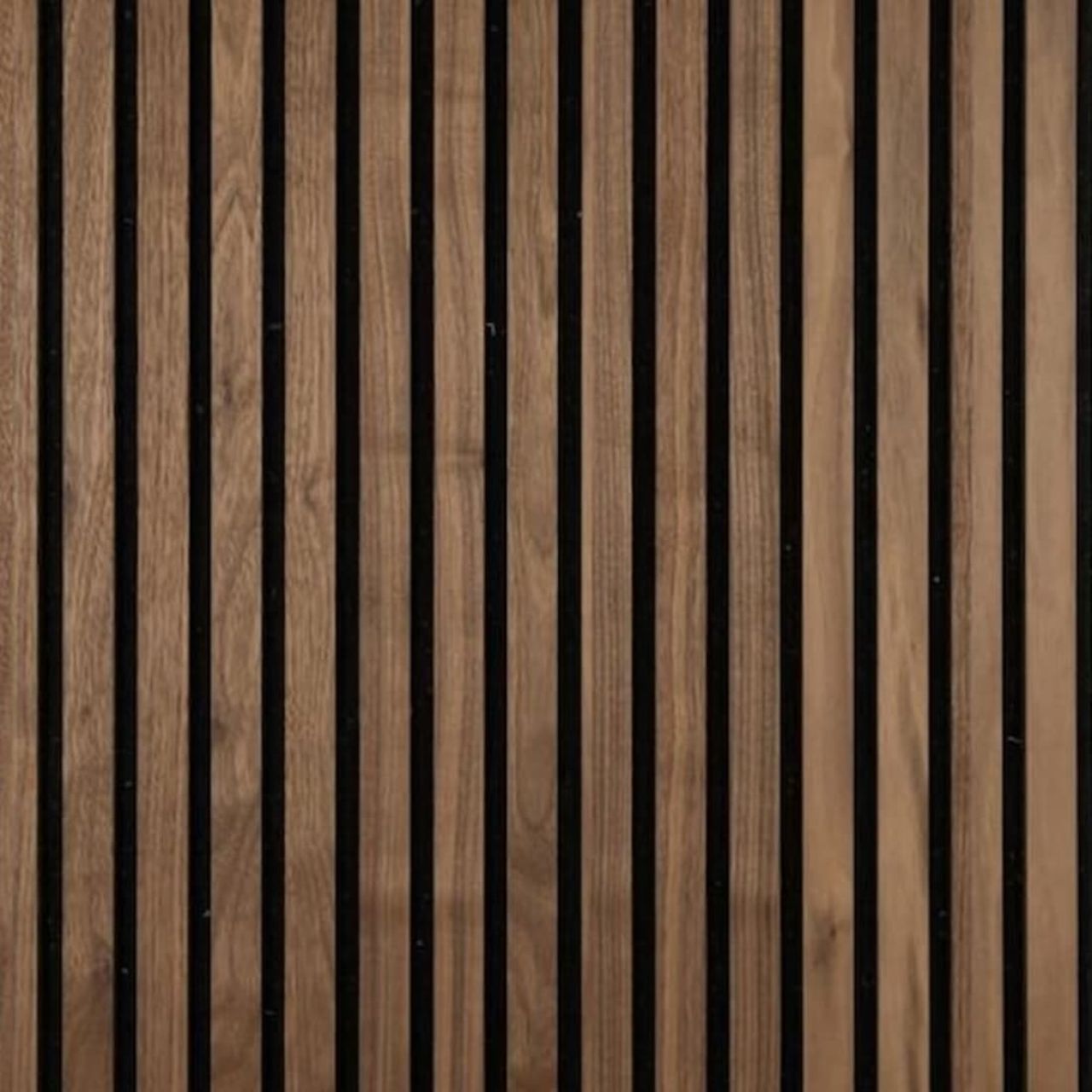

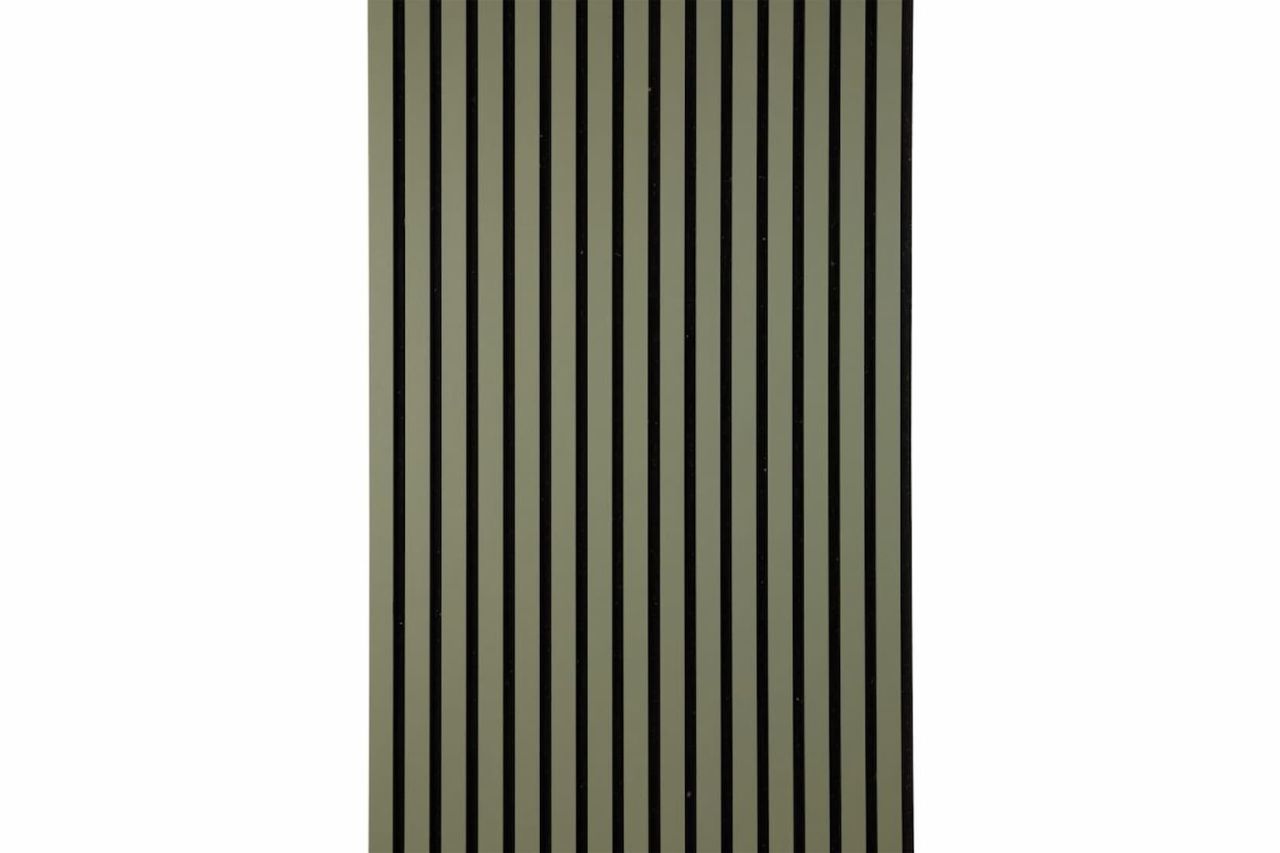

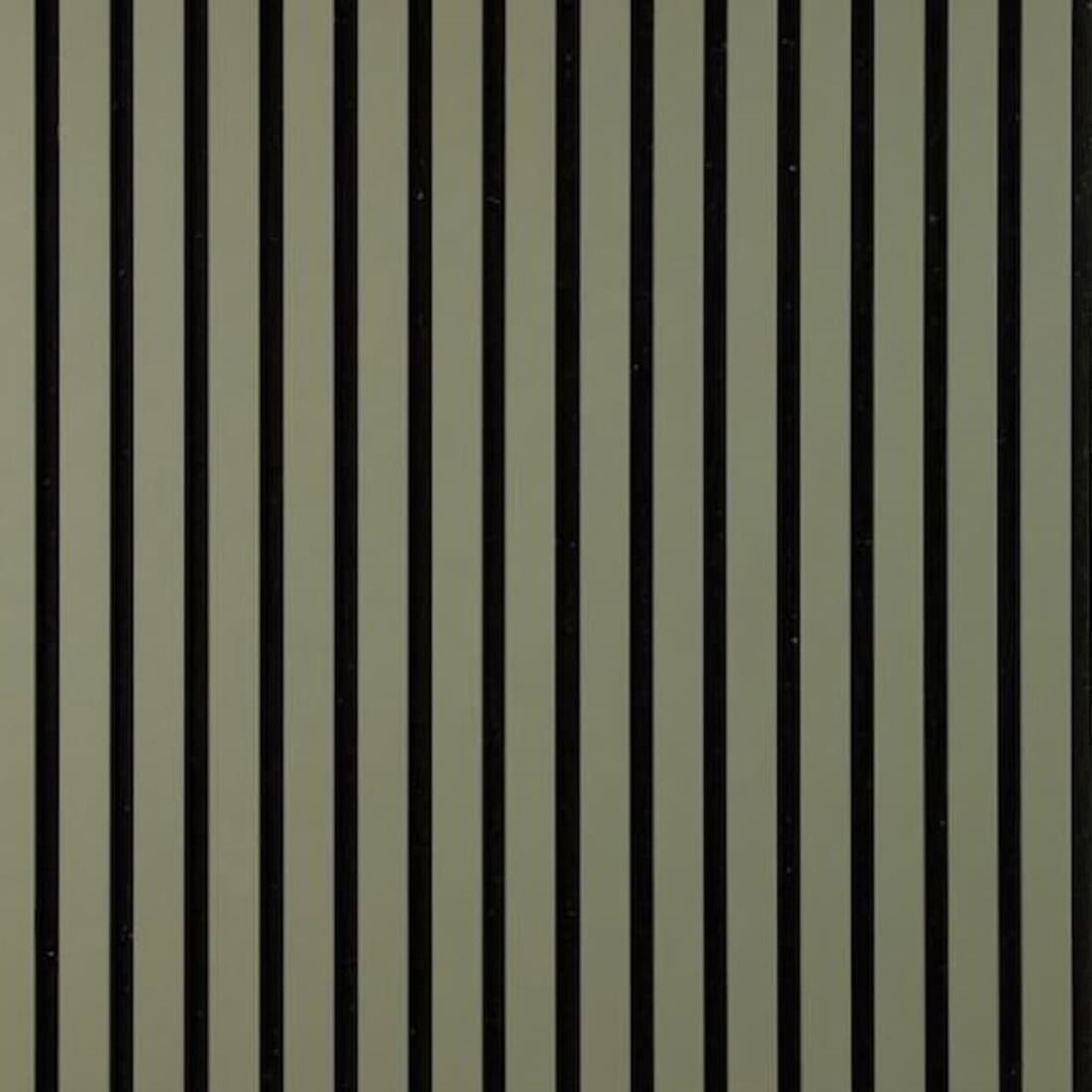

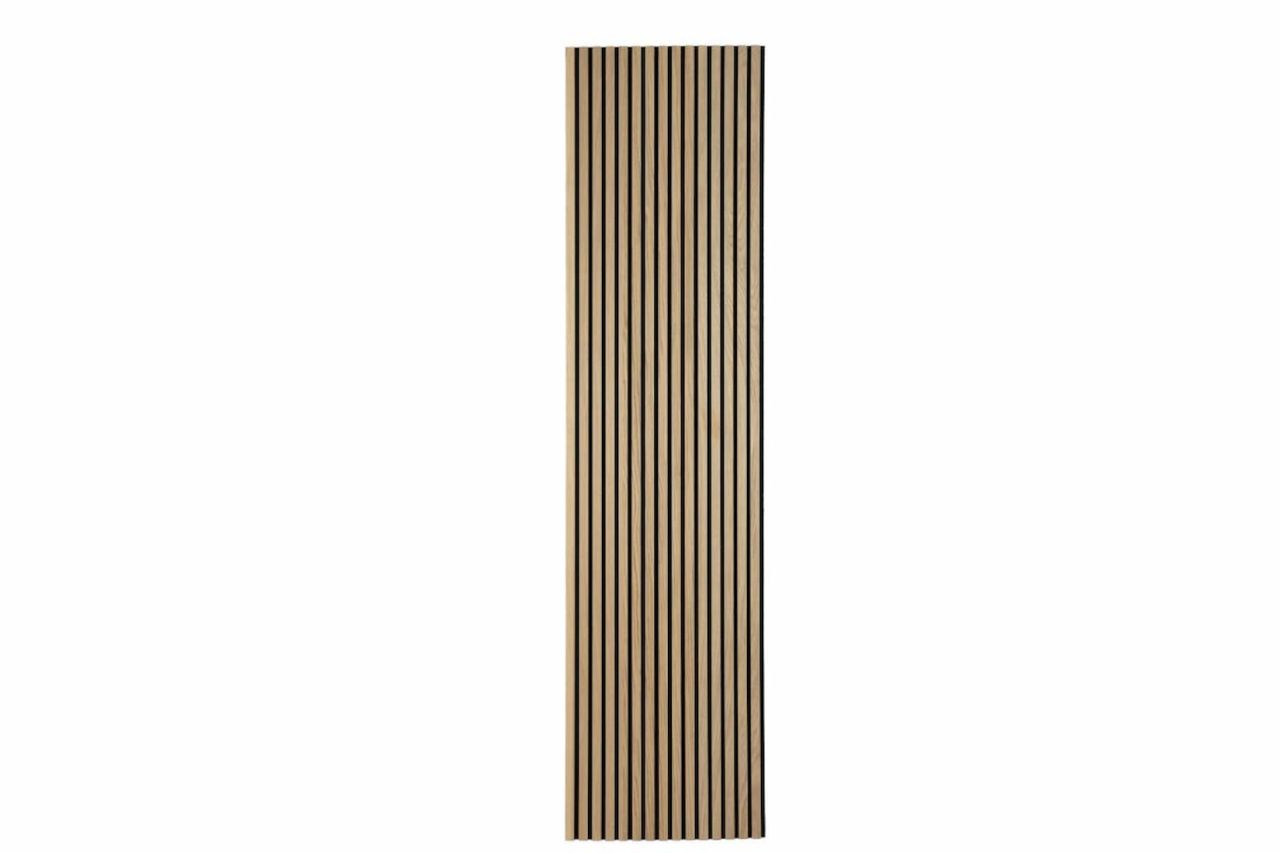

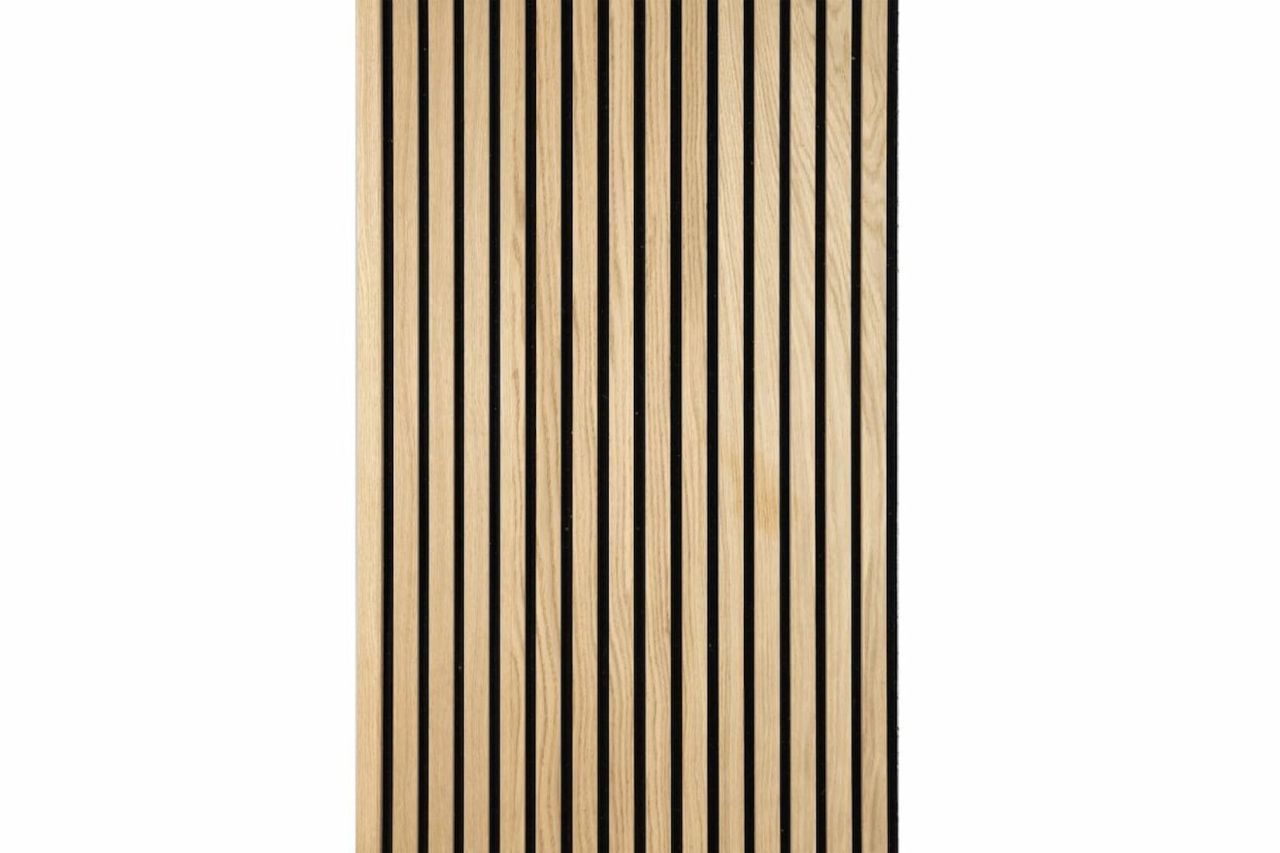

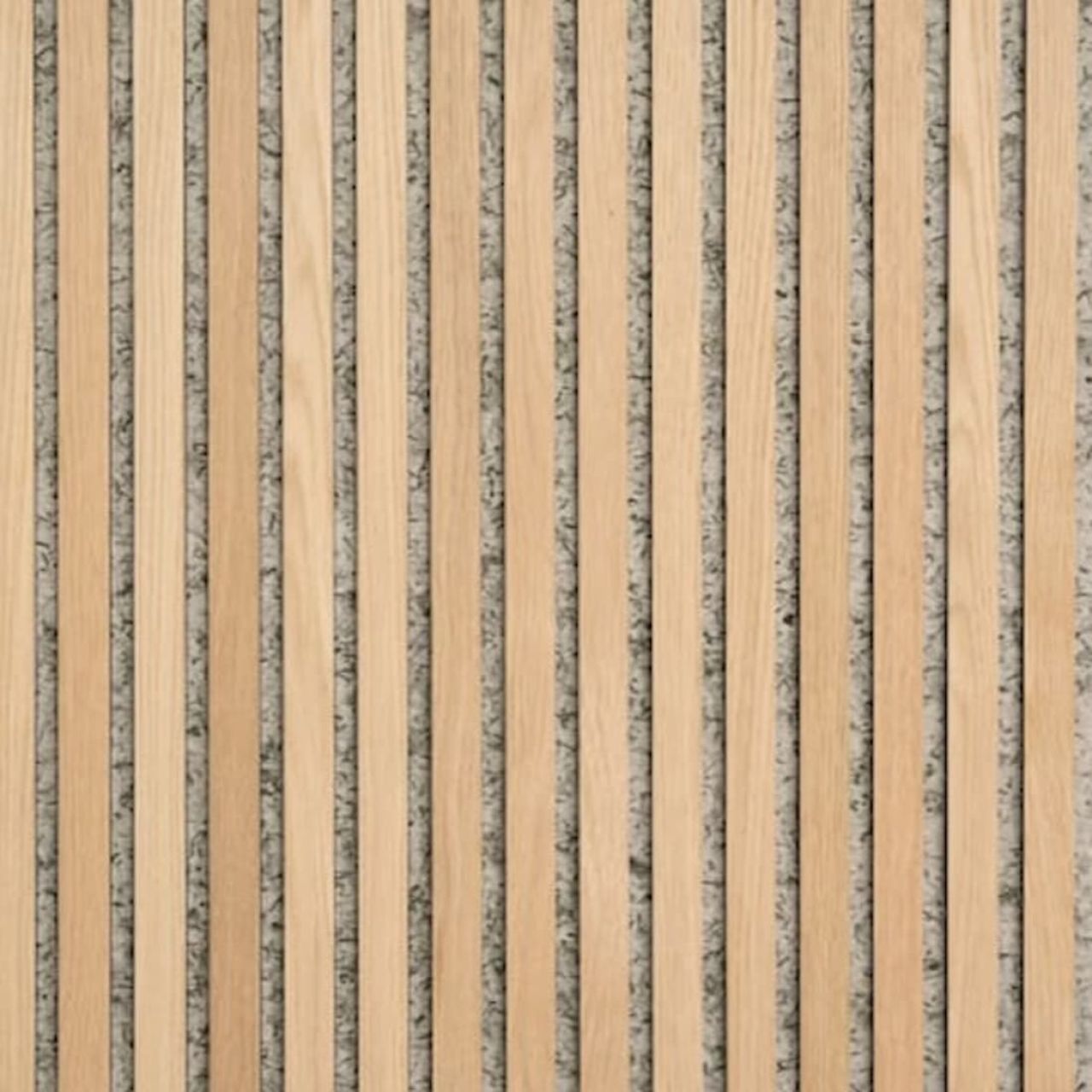

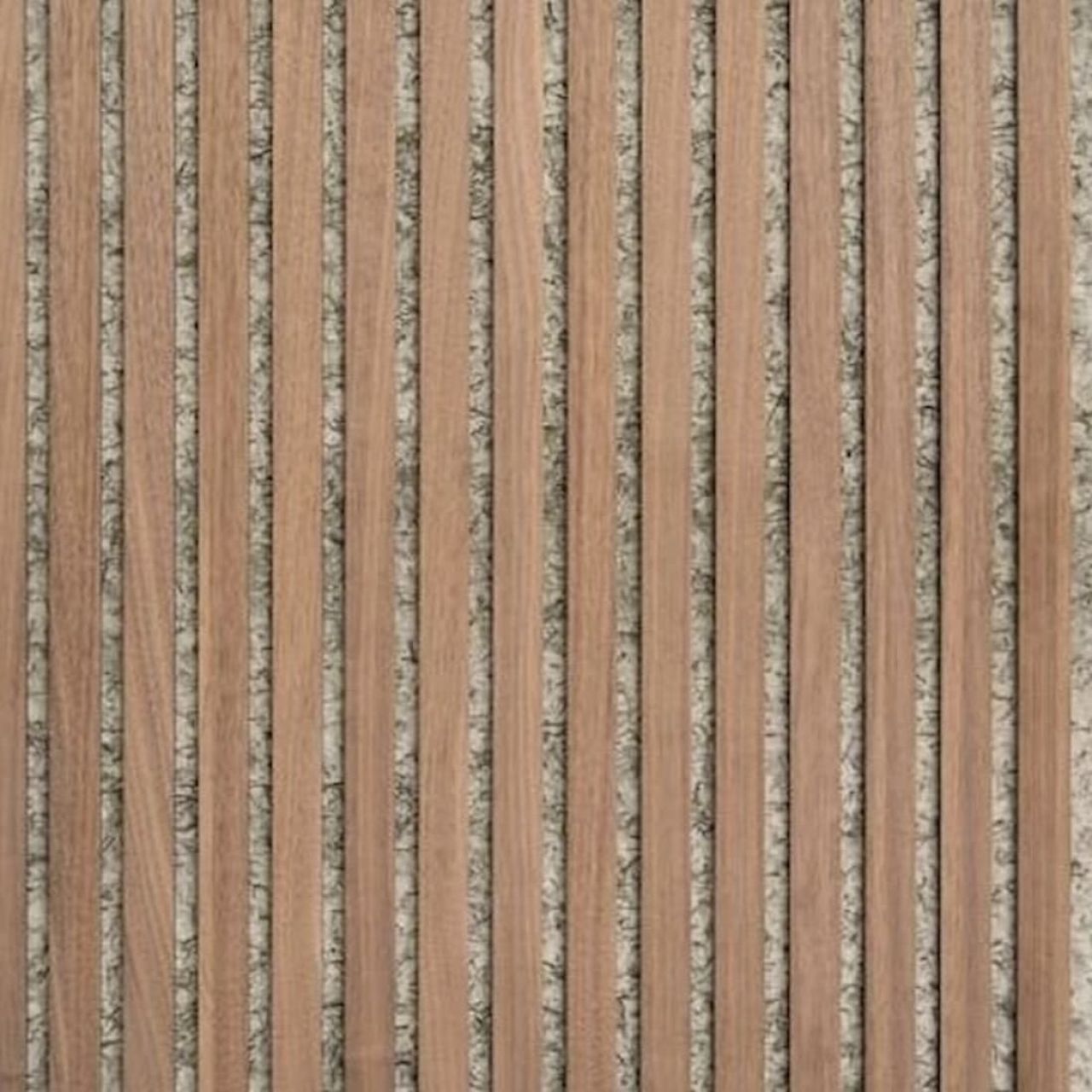

Some of our combinations

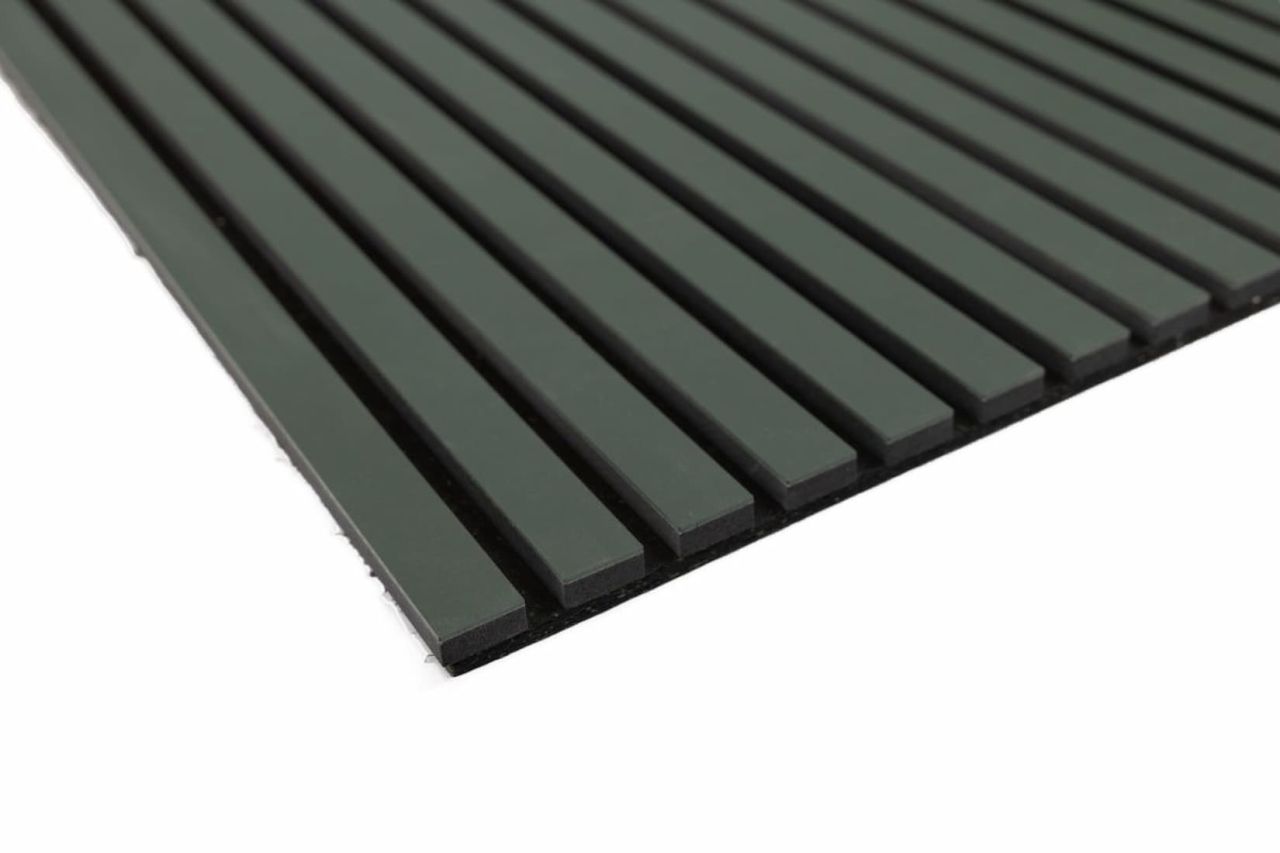

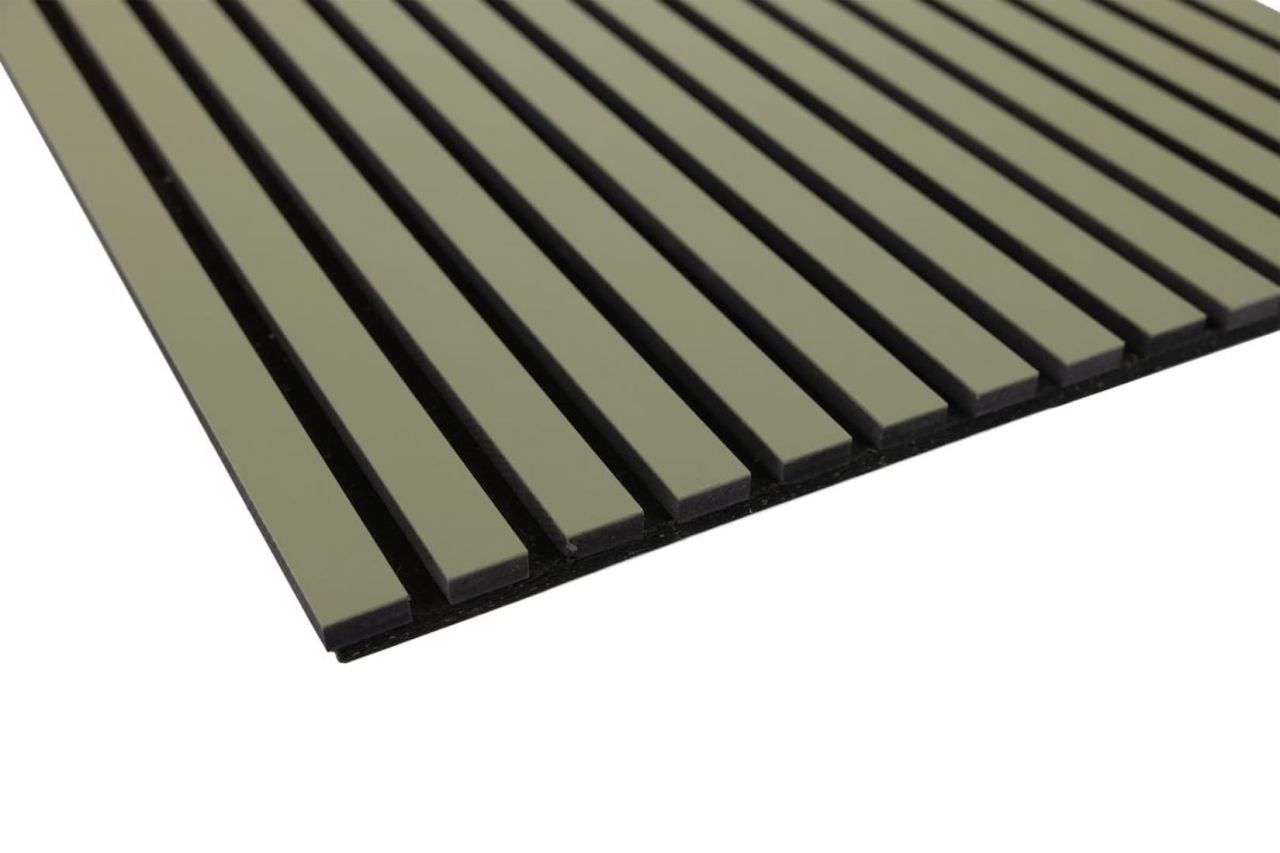

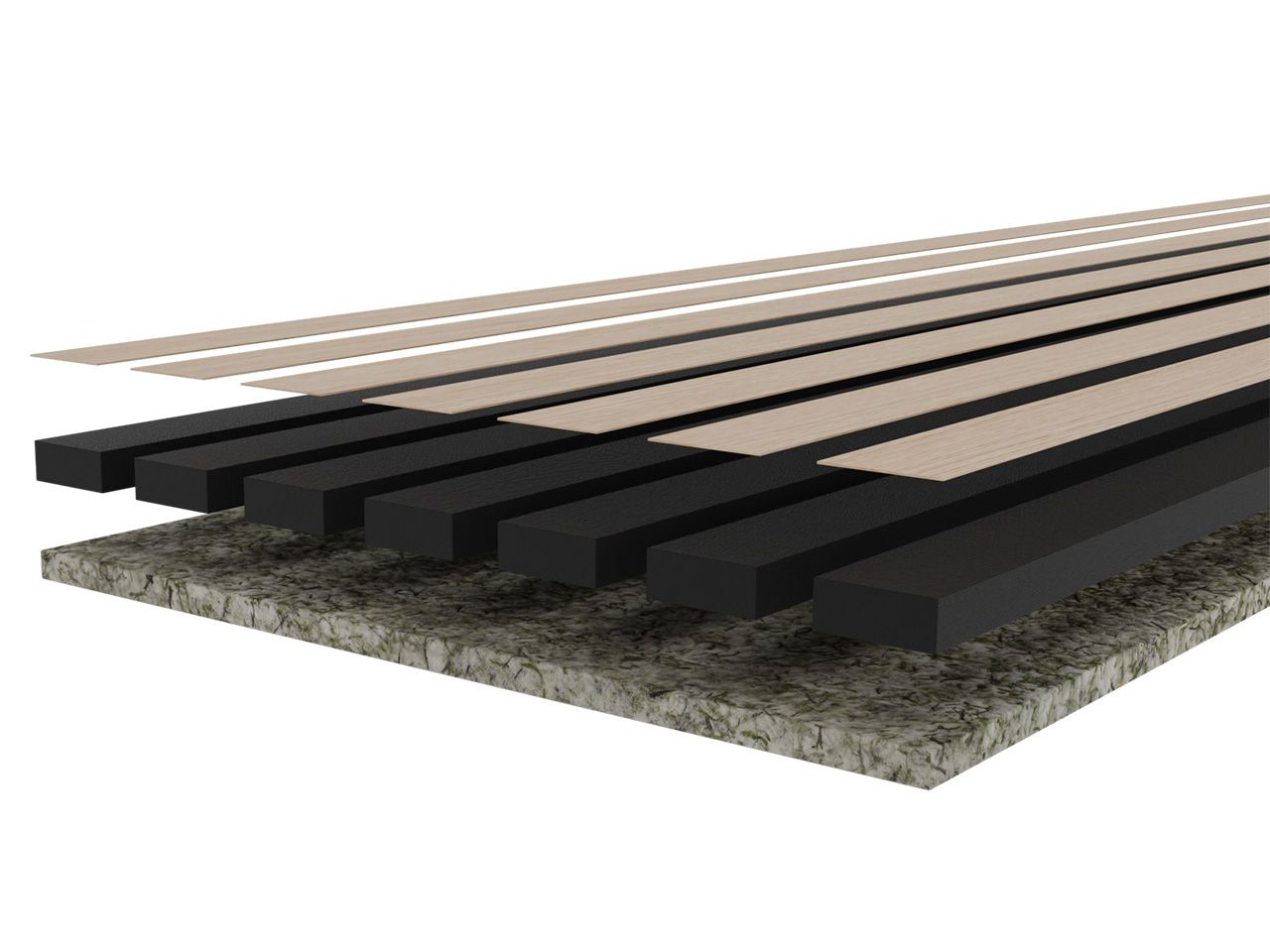

The panel’s construction

The veneer

The slat

The felt

The GreenOption Story

Stadiums and sports arenas around the world have started using artificial turf, but after 10 years, even high-quality artificial turf has worn down. In most cases, this means disposing the pitch through incineration – with a significant negative environmental impact.

With Re-Match’s solution, football pitch owners can dispose their worn-out artificial turf in a better, cheaper, and environmentally safe way.

The average life of a football pitch is 10 years based on normal quality, proper installation, maintenance, exposure to sunlight and normal use throughout its lifetime. It typically includes 7,000 m2 / 75,347 square feet and weighs around 220 tons / 242.51 US tons divided into:

60% sand

30% rubber granulate

5% backing

5% grass fiber

What is special about our Upcycled Turf panel is our felt on the back, which is made of 100% recycled artificial turf that is cut into small pieces and then mixed into a felt, which gives the beautiful and unique expression. Then our MDF slats are mounted with a real wood veneer on the front. This means that nuance differences may occur in the expression of the veneer.